Armored Control Cable Ensuring Reliable Communication and Safety in Industrial Applications

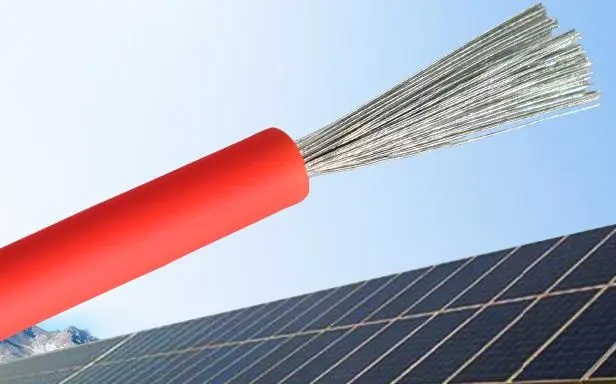

Introduction Armored control cables play a crucial role in various industrial applications where reliable communication and safety are paramount. These cables are designed to provide protection against external elements, mechanical damage, and electromagnetic interference, ensuring uninterrupted signal transmission and control in challenging environments. In this article, we will delve into the importance of armored control cables, their construction, key features, applications, and benefits in industrial settings. Importance of Armored Control Cable In industrial settings, the control and transmission of signals are critical for the operation of machinery, equipment, and systems. Armored control cables are specifically engineered to withstand harsh conditions such as extreme temperatures, moisture, chemicals, and physical stress, which are common in industrial environments. By providing a protective outer layer, armored cables ensure the integrity and longevity of the communication and control systems, minimizing downtime and maintenance costs. Construction of Armored Control Cable Armored control cables are typically constructed with multiple layers of materials to provide mechanical strength, protection, and insulation. The core of the cable consists of conductors, usually made of copper or aluminum, which carry electrical signals. These conductors are insulated with materials such as PVC, XLPE, or polyethylene to prevent signal interference and ensure reliable transmission. The conductors are then surrounded by a metallic armor layer, which can be made of steel, aluminum, or other alloys. The armor layer provides protection against physical damage, moisture, and electromagnetic interference. Finally, the outer sheath is added to shield the cable from environmental factors and further enhance its durability. Key Features of Armored Control Cable 1. Mechanical Strength: The metallic armor layer in armored control cables provides excellent mechanical strength, allowing the cables to withstand bending, crushing, and impact without compromising signal transmission. 2. Protection Against External Elements: Armored control cables are designed to resist moisture, chemicals, UV radiation, and other environmental factors, making them ideal for outdoor and harsh industrial environments. 3. Electromagnetic Interference (EMI) Shielding: The metallic armor layer acts as a shield against electromagnetic interference, ensuring reliable signal transmission in areas with high levels of electrical noise. 4. Durability and Longevity: The robust construction of armored control cables makes them highly durable and long-lasting, reducing the need for frequent replacements and maintenance. Applications of Armored Control Cable Armored control cables find a wide range of applications across various industries where reliable communication and control are essential. Some common applications include: 1. Industrial Automation: Armored control cables are used in automated manufacturing processes, robotic systems, and control panels to transmit signals and commands with precision and reliability. 2. Oil and Gas Industry: In oil refineries, offshore platforms, and petrochemical plants, armored control cables are employed to ensure safe and efficient operation of equipment and machinery in hazardous environments. 3. Mining Operations: Armored control cables are essential for powering and controlling heavy machinery, conveyor systems, and communication networks in mining operations where rugged and reliable cables are required. 4. Transportation Systems: Armored control cables play a vital role in railway signaling systems, airport control towers, and traffic management applications where uninterrupted communication is crucial for safety and efficiency.  Benefits of Armored Control Cable 1. Enhanced Safety: Armored control cables provide a high level of protection against physical damage, fire hazards, and electrical faults, reducing the risk of accidents and ensuring the safety of personnel and equipment. 2. Rubber Sheathed Cable and Performance: The robust construction of armored control cables ensures consistent signal transmission, control accuracy, and system reliability, even in harsh industrial environments. 3. Cost-Effectiveness: Although armored control cables may have a higher initial cost than standard cables, their long lifespan, durability, and minimal maintenance requirements make them a cost-effective solution in the long run. 4. Compliance with Industry Standards: Armored control cables are designed and manufactured according to industry standards and regulations to meet the specific requirements of different applications and ensure quality and performance. Conclusion Armored control cables play a vital role in ensuring reliable communication, control, and safety in industrial applications where harsh conditions and environmental factors pose challenges to traditional cables. With their robust construction, mechanical strength, and protection against external elements, armored control cables are the preferred choice for industries such as manufacturing, oil and gas, mining, and transportation. By investing in high-quality armored control cables, companies can enhance the efficiency, safety, and longevity of their industrial systems, leading to improved productivity and operational performance.

Benefits of Armored Control Cable 1. Enhanced Safety: Armored control cables provide a high level of protection against physical damage, fire hazards, and electrical faults, reducing the risk of accidents and ensuring the safety of personnel and equipment. 2. Rubber Sheathed Cable and Performance: The robust construction of armored control cables ensures consistent signal transmission, control accuracy, and system reliability, even in harsh industrial environments. 3. Cost-Effectiveness: Although armored control cables may have a higher initial cost than standard cables, their long lifespan, durability, and minimal maintenance requirements make them a cost-effective solution in the long run. 4. Compliance with Industry Standards: Armored control cables are designed and manufactured according to industry standards and regulations to meet the specific requirements of different applications and ensure quality and performance. Conclusion Armored control cables play a vital role in ensuring reliable communication, control, and safety in industrial applications where harsh conditions and environmental factors pose challenges to traditional cables. With their robust construction, mechanical strength, and protection against external elements, armored control cables are the preferred choice for industries such as manufacturing, oil and gas, mining, and transportation. By investing in high-quality armored control cables, companies can enhance the efficiency, safety, and longevity of their industrial systems, leading to improved productivity and operational performance.